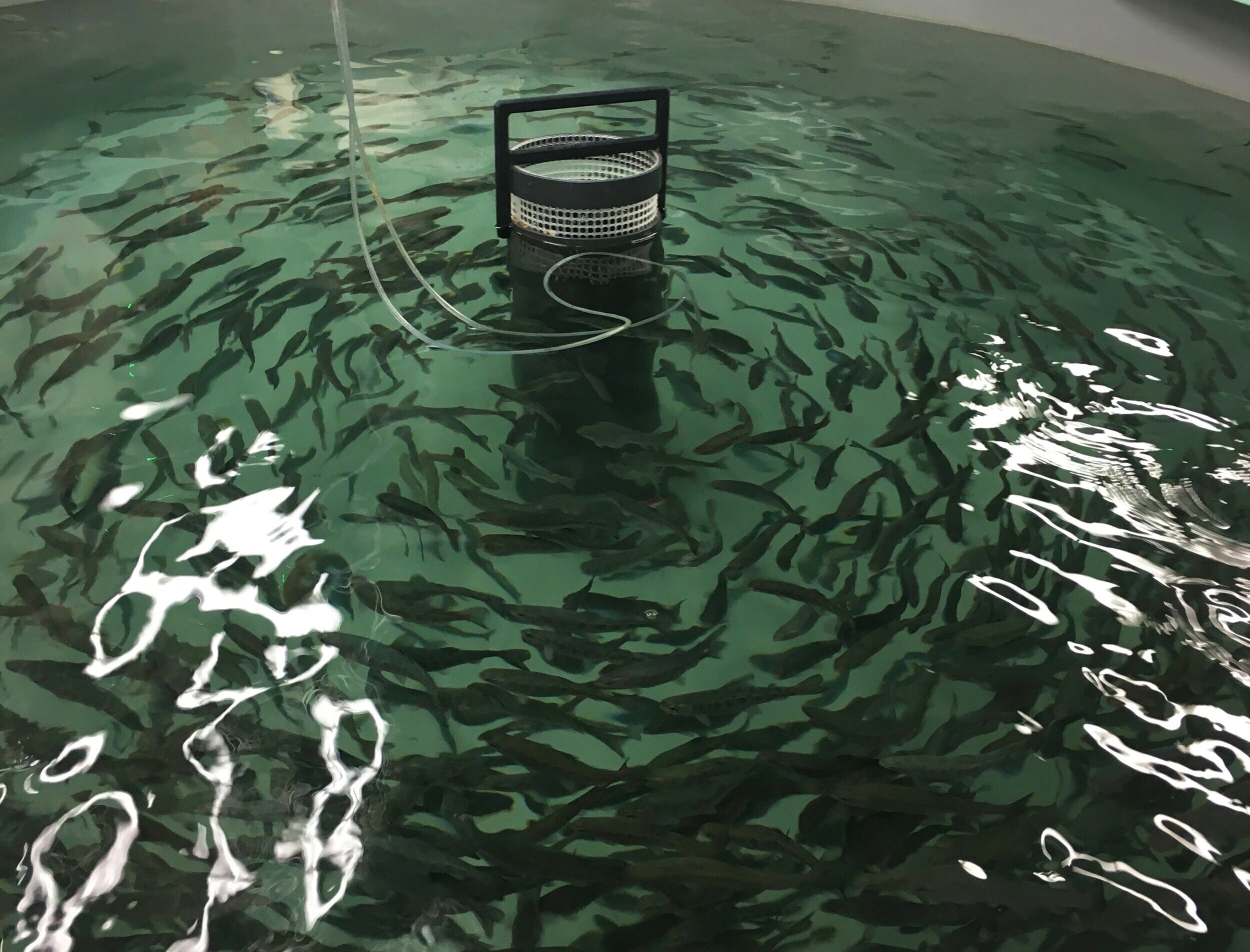

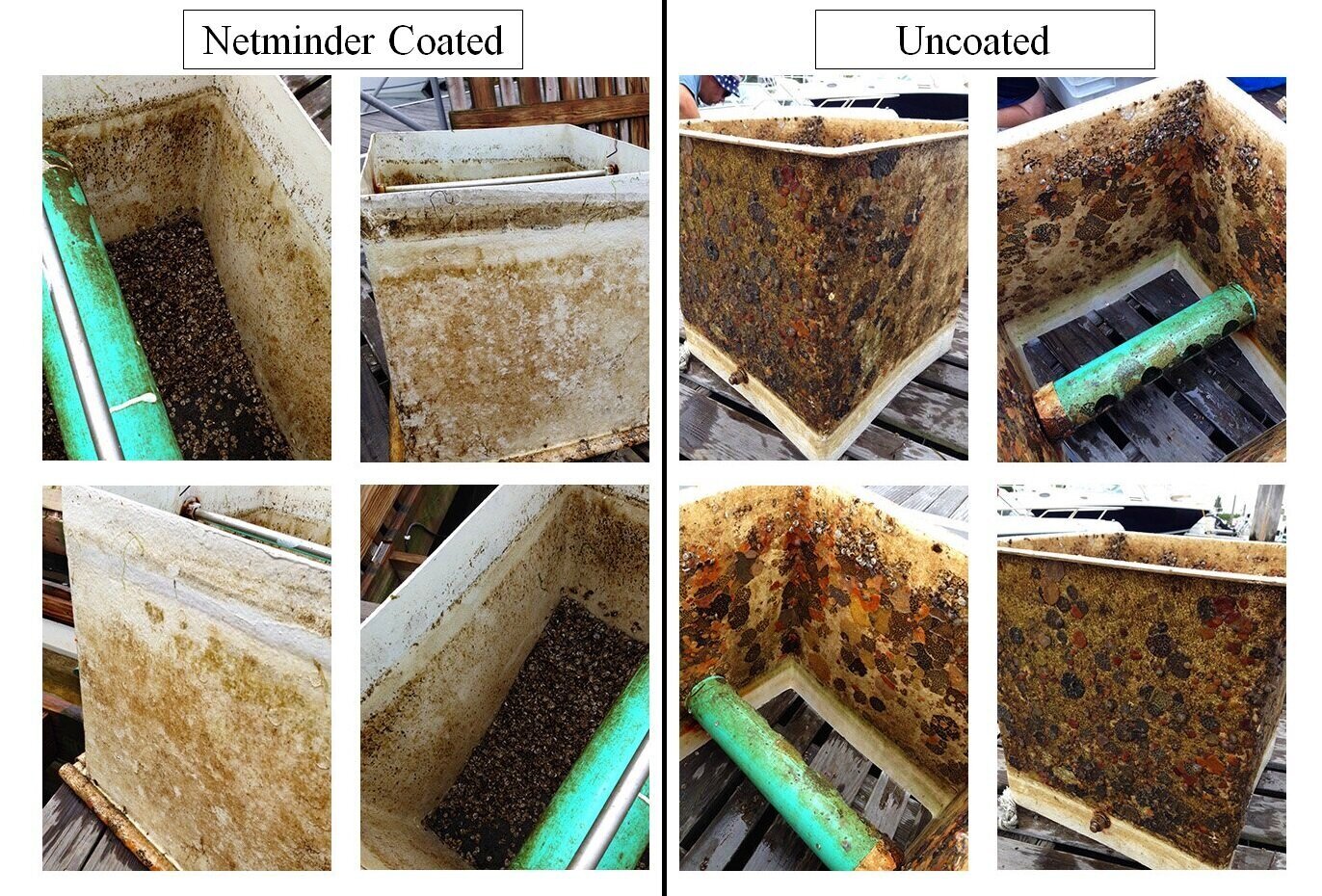

FLUPSY

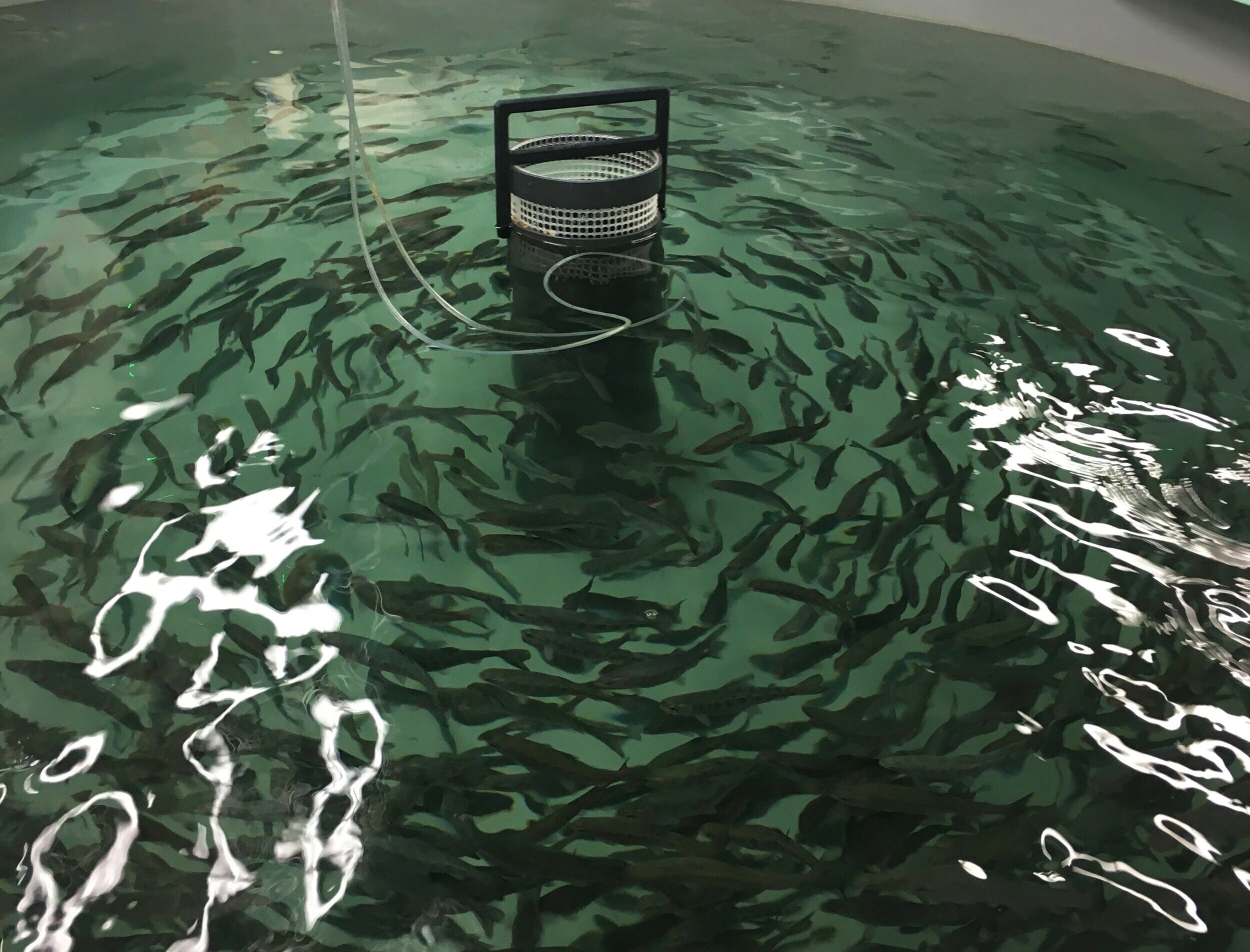

A floating upweller system (FLUPSY) consists of a raft constructed with several culture chambers that hold oyster seed. Sea water is pumped through the culture chambers at a rate that far exceeds what is available through natural currents. This system greaty increases the oyster seed's rate of development and effectively shortens the growing season allowing us to harvest sooner and keep costs down.

STIRRING THE SEED

Dan Ward, co-owner of Ward Aquafarms, stirs this season's oyster seed in the FLUPSY. These oysters are only the size of a grain of sand so they easily clog the netting of the FLUPSY and restrict water intake if not stirred daily.

UPWELLER UP CLOSE

Fresh water continuously pumps through the upweller which speeds up the oysters development.

250,000 OYSTERS

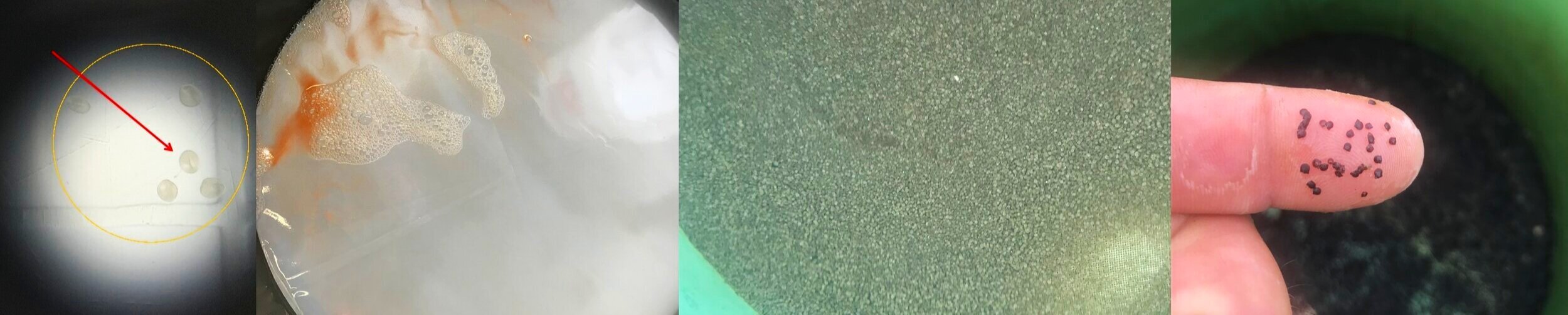

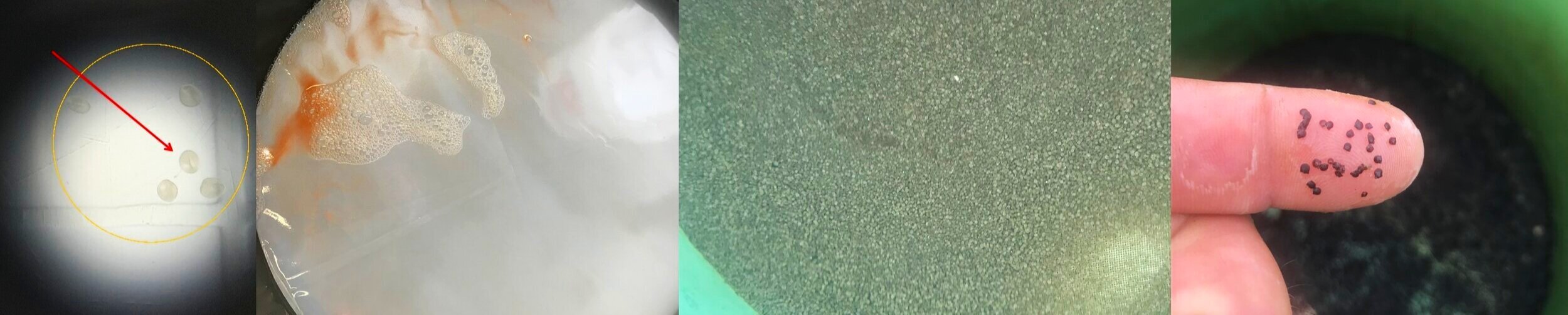

This is how oyster seed arrives to Ward Aquafarms from the hatchery. This bundle of 250,000 oysters grew up to be our first harvest in 2013.

OYSTER SEED

This is what oyster seed looks like when it has just been added to the FLUPSY. These guys will grow to be several centimeters in length during the next couple of weeks.

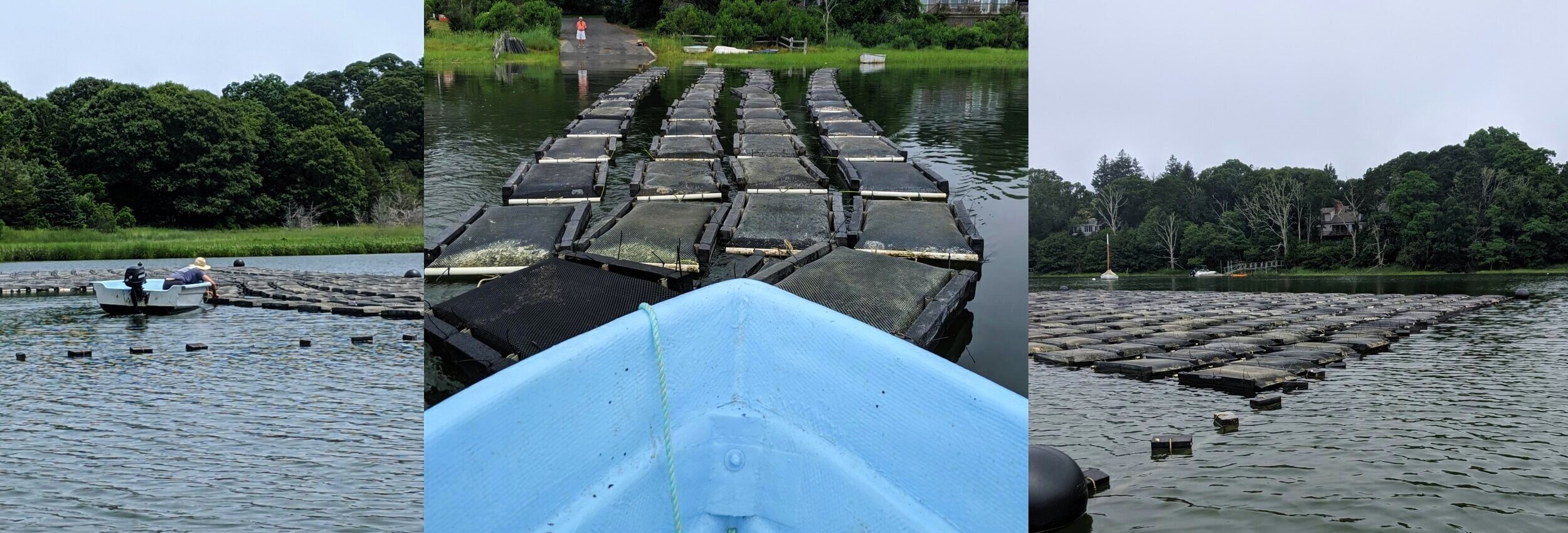

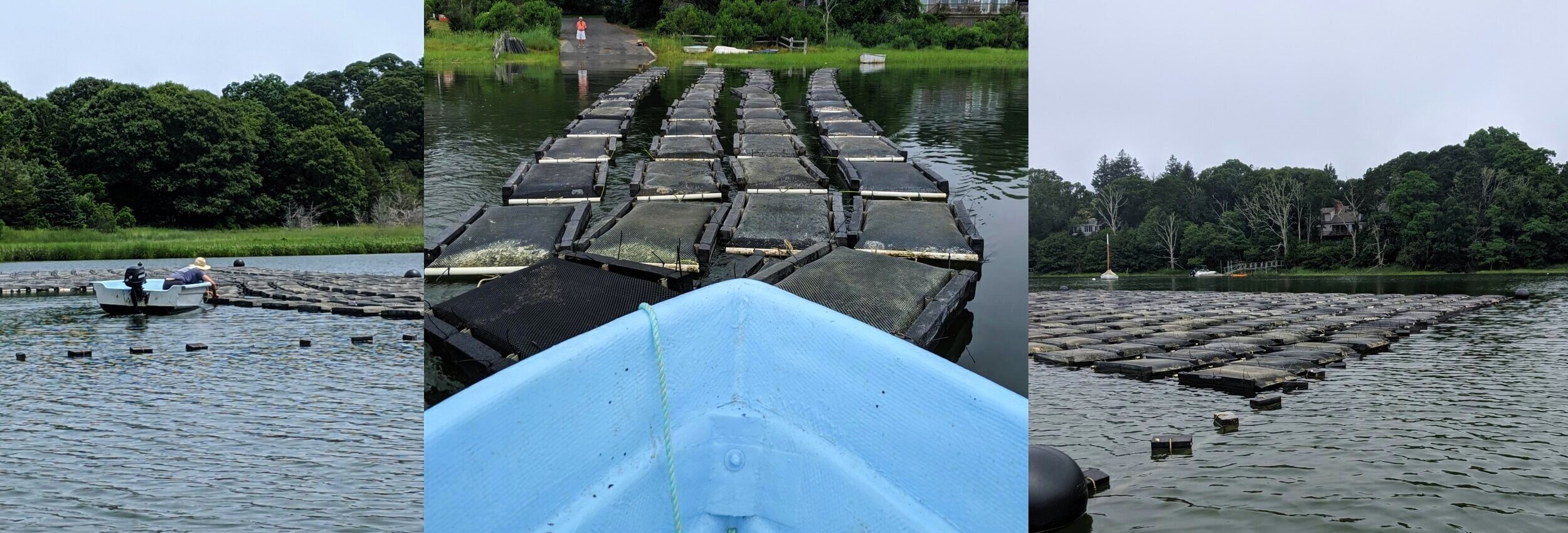

OYSTER BAGS

These bags are stored in cages under water, then dragged up on dock and sorted into different size categories, re-bagged, and brought back down into cages. This process is done every two weeks.

MEGANSETT SUNSET

View from the farm after a hard day's work.

Life is good.

GROWING OYSTERS

At 1-2", these oysters are making progress but still have a ways to go before they're market ready.

NEW BEGINNINGS

This bag contains 250,000 oyster seeds and was the start of Ward Aquafarms. Starting out at just at 1.5mm (about the size of a grain of sand) these seeds are grown in the upweller to about 1â„2-1â€Â, when they can then be moved to the grow out site.

GETTING BIGGER

Not ready yet but looking healthy!

BRINGIN 'EM UP

This cage has been brought up to the surface so the oysters can be sized and sorted. Sizing and sorting the entire farm takes about 6 hours.

THE VIEW IS FREE

View of Megansett Harbor from one of the docks.

THE BARGE

This one of a kind pontoon boat has been modified to make it ideal for aquafarming.

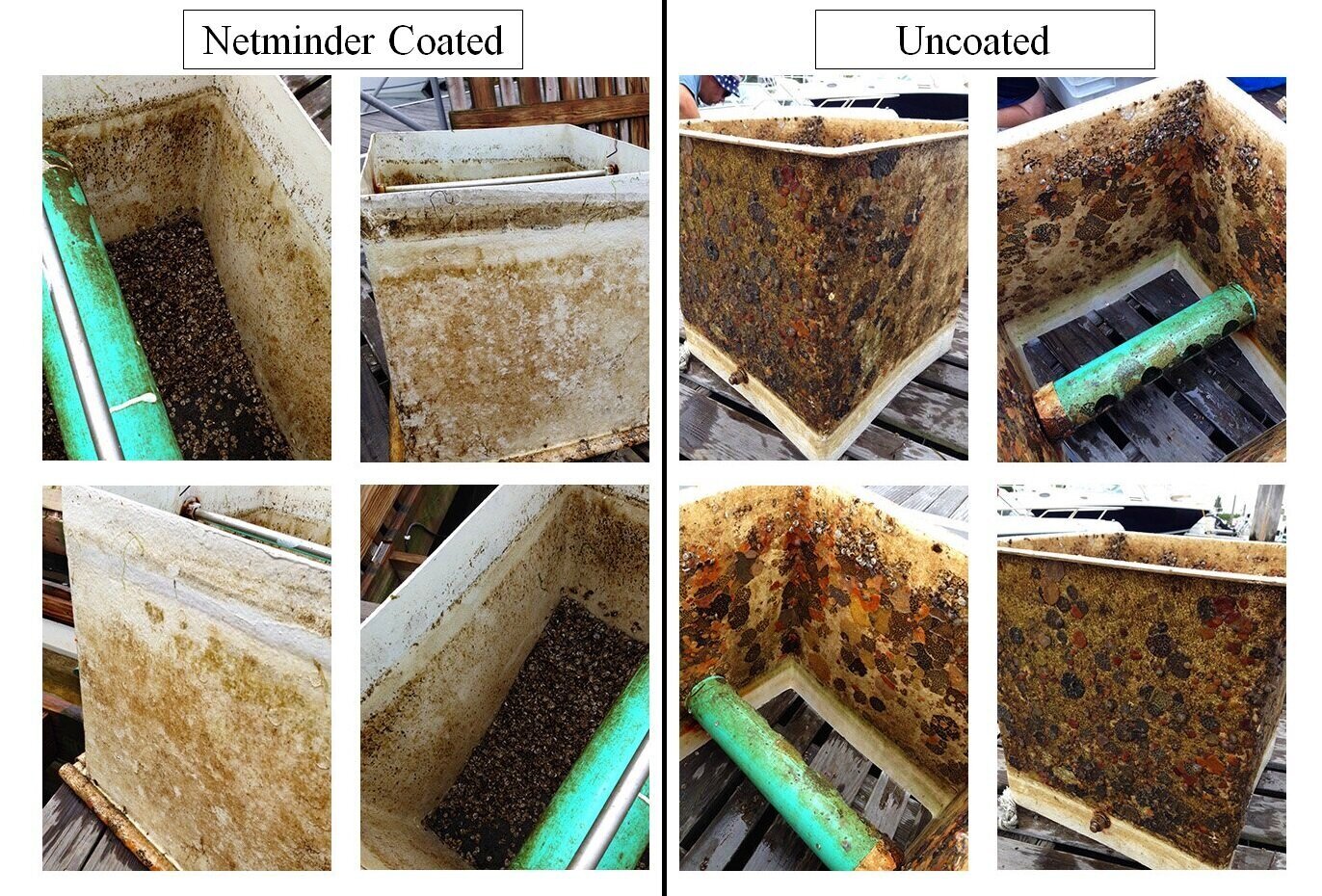

STAGE 1 KELP

These tanks are used in the early stages of kelp cultivation.

NECESSARY EQUIPMENT

The ramp and winch pictured here are invaluable to the Ward Aquafarms barge.

PRECISE AND SUSTAINABLE

Every oyster harvested is carefully measured to ensure it meets proper size specifications.

THAT'S IT!

A beautifully developed oyster. This is why we work so hard.

FIRST DOZEN!

This picture always brings back good memories. Ward Aquafarms' first dozen oysters. In case you're wondering, yes they were delicious.

GROW SITE

This is what the grow site looks like. The buoys indicate the farm boundaries and cage locations.

100,000 OYSTER SEEDS

Ever wonder what 100,000 baby oysters look like? Well, now you know.

MEASURING FOR GROWTH

These oysters are just starting their journey in the upweller.

DIPLOIDS AND TRIPLOIDS

Here at Ward Aquafarms, we grow diploid and triploid oysters. The triploid oyster grows faster and is more disease-resistant than the diploid oyster. And, just as important, they can be eaten in summer without the loss of taste and texture that afflicts bivalves tied to spawning cycles.

BARGE LAUNCH

On the way to launch the barge for the first time. June 2013.

UPWELLER SILO

Up close view of one upweller silo mid-season.